| dc.contributor.advisor | Ahmed, Ramadan | |

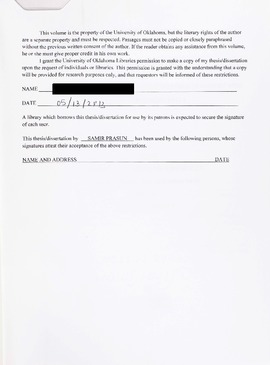

| dc.contributor.author | Prasun, Samir | |

| dc.date.accessioned | 2017-11-08T18:12:38Z | |

| dc.date.available | 2017-11-08T18:12:38Z | |

| dc.date.issued | 2013 | |

| dc.identifier.uri | https://hdl.handle.net/11244/52411 | |

| dc.description.abstract | The use of foam for underbalanced drilling applications is increasing significantly. This is because foam exhibits properties, which are desirable when drilling depleted and low-pressure wells. However, a good knowledge of foam hydraulics and cuttings transport (hole cleaning) is essential for successful applications of foam drilling technology. Cuttings transport with foam in inclined wells is still less understood. Change in inclination makes it difficult to predict the bed height and pressure profiles along the wellbore. Variations in drilling parameters have significant effects on the foam properties and cuttings transport mechanisms. This investigation focuses on understanding the effects of drilling parameters on the cuttings concentration and pressure profiles. Properly designed foam drilling requires efficient hole-cleaning thus avoiding any lost circulation, formation damage and stuck-pipe. | |

| dc.description.abstract | A new transient wellbore hydraulics and cuttings transport model has been developed. The model incorporates frictional pressure loss and hydrostatic pressure change occurring in the wellbore, and it predicts foam flow properties (density, viscosity, velocity, quality, and pressure) at different depths of the well bore. | |

| dc.description.abstract | In order to predict the cuttings bed formation in horizontal wells, a mechanistic hole-cleaning model consisting of two layers has been utilized. The model is based on torque balance for a particle on the surface of a bed formed in build-up or horizontal section of a wellbore. In addition, a new model has been formulated for the local shear stress and local fluid velocity in the eccentric annulus to be applied in the torque and force balance equations. A computer program (simulator) has been developed to solve the model equations using finite difference method to calculate cuttings concentration and pressure profiles as a function of time. | |

| dc.description.abstract | Model predictions were compared with published experimental data and the model is fine-tuned to minimize discrepancies. Extensive parametric study was conducted to investigate the effects of different drilling parameters on cuttings concentration and pressure profiles. Results show how the cuttings bed front moves up in the annulus along the build-up and horizontal sections. A detailed sensitivity analysis of the effects of gas and liquid flow rates, foam quality, and back pressure on the cuttings concentration and pressure profiles was performed. The effect of inclination on the equilibrium bed height and critical foam velocity were studied in detail. The model also takes into account the liquid influx during underbalanced drilling. Parametric study on the effects of liquid influx on the foam properties and cuttings concentration was conducted. | |

| dc.description.abstract | Model predictions showed a good match with experimental results for concentric horizontal annulus except at higher polymer concentrations (greater than 0.25%). The simulation results show that bed height and bottom-hole pressure are quite sensitive to the changes in surface foam injection rates and back-pressure, thereby can be best optimized by properly adjusting the input parameters. In extreme underbalanced conditions, water-influx can result in reduction of foam quality (as much as 23%) without affecting much of its hole-cleaning performance. The result also suggests that hole-cleaning is a function of inclination. The bed height increases with increase in inclination angle until a critical angle of 90°-φ (φ is the angle of repose) after which, it reduces. | |

| dc.format | xiii, 100 leaves : illustrations (some color) ; 28 cm. | |

| dc.language | en_US | |

| dc.subject | Foam | |

| dc.subject | Drilling muds | |

| dc.subject | Horizontal oil well drilling | |

| dc.subject | Mewbourne School of Petroleum and Geological Engineering | |

| dc.title | Numerical simulation of transient cuttings transport with foam in horizontal wells | |

| dc.type | Thesis | |

| dc.type | text | |

| dc.contributor.committeeMember | Shah, Subhash | |

| dc.contributor.committeeMember | Civan, Faruk | |

| dc.date.manuscript | 2013 | |

| dc.thesis.degree | Master of Science | |

| ou.group | Mewbourne College of Earth and Energy::Mewbourne School of Petroleum and Geological Engineering | |